How to mount an aluminum window without compromises

Installing a no-compromise aluminum window requires only the refusal to make these compromises and the willingness to work with a team of professionals, obviously at a higher total cost.

We feel that avoiding compromises in the installation of an aluminum window requires various technological equipment. It’s just an illusion. In a poorly prepared team, these equipment can only be simple objects to support the offer. Using them to their true potential requires a high level of training and long-term experience, situations that are increasingly rare. The mere presence of expensive equipment in the equipment of the team chosen for the installation of the aluminum window is not a proof of the quality of the installation.

Installing an uncompromising aluminum window requires honest and constructive collaboration between the architect, the site manager and the carpentry team. As a manufacturer of aluminum doors and windows, we offer a full range of services – consulting, measurements, design, manufacturing, mount and maintenance.

The experience of 30 years in this field has confirmed to me the fact that most mistakes are made from the first phase, namely – during measurements. For this reason, we must ensure that the dimensions of the carpentry have been taken correctly and responsibly.

At this stage, especially in the case of carpentry on several sides, it is checked whether the right angles necessary for the correct joining of the profiles have been respected. In the situation where you have opted for a project with modern elements, we recommend that we be contacted by the architect or the site manager from the project stage to communicate the details and safety elements specific to this category of work.

Builders, in order not to repair the glazing bars twice, recommend postponing this stage after the windows have been installed. I always recommend that the jambs be straightened before the windows are installed. It is recommended that all frames be straightened before measurements. Where the situation warrants, I recommend that final measurements be delayed until all errors have been corrected despite all external pressures.

From the moment the measurements were taken for execution, we take full responsibility for the quality of the window.

You, as the beneficiary, want the window to be flawless in the end, and not helplessly stand by in the face of a dispute between the teams involved in the construction. Overlooking certain construction errors will implicitly lead to the need to compensate for them by the windowing system – an option that is not always possible or involves certain compromises.

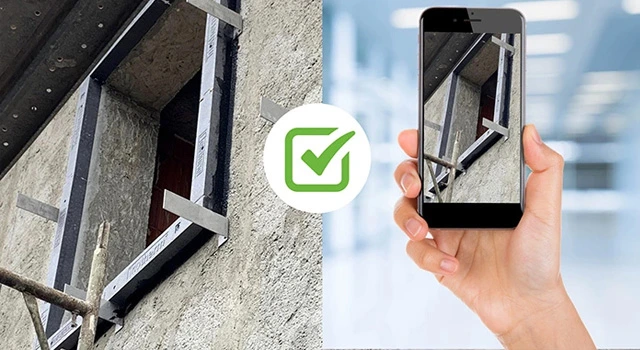

This is the first decisive moment. This is the time when we recommend identifying all construction errors and correcting them. This is the moment when we recommend to say no to compromises and to take responsibility for every decision. In practice, each team of builders tends to hide their own errors knowing that they will be corrected by the next team. The next team, in the desire not to increase the total budget with additional expenses, pretends not to see them. After the aluminum window is installed, the beneficiary has the opportunity to measure certain distances himself.

This is when all errors are easily visible. We believe that every team that measures for an aluminum window has the obligation to identify and communicate all construction errors in the building. At this stage we can discuss high-performance technological equipment and the level of training of the team. Fortunately, there is a wide range of equipment that allows us to quickly measure certain distances and angles.

The second decisive moment is the choice of materials used. By materials used we mean the profile model used to manufacture the window, the glass model and the window mounting system. The choice of materials by customers is largely the responsibility of those who proposed them. It is our duty as professionals to explain to you what the performance differences are for the proposed materials. Most bona fide buyers do not know the technical characteristics of the goods they are paying for. They believe in the recommendations of so-called professionals. For a professional carpentry installation, we need the best quality materials.

We recommend not making compromises when choosing the window profile for your home. It can have positive consequences for energy efficiency, safety, comfort and quality of life inside the home. It is important to invest in a high quality profile. An insulating glass that meets all your needs and ensures a comfortable and sustainable home in the long term. Quality joinery, such as double glazed windows and doors, plays a crucial role in maintaining the internal temperature of the home. It will ensure adequate thermal insulation, thus reducing the subsequent costs of heating and cooling the home.

Assembly with polyurethane foam or metal preframes.

Using polyurethane foam for the installation of aluminum joinery, from our point of view, is not the best solution. There are carpentry fitters pros and cons. We avoid installing aluminum joinery using polyurethane foam as much as possible. Reports received over time have confirmed to us that when the lid is not closed tightly, the polyurethane foam degrades and loses its insulating properties. The only advantage of polyurethane foam is the low cost, the speed of installation of the joinery and a minimum level of training of the assembly team.

The pre-frames are installed in advance in the area where the aluminum window frames are to be installed. They are recommended for places where the masonry has low resistance and are installed in the thermal insulation area of the house. The fixing of the pre-frames will be done before the installation of the thermal insulation and the fixing of the pre-frames will be done directly on the wall with screws. The sealing of the joints between the pre-frame and the aluminum joinery will be done with pre-compressed strips. The choice of pre-compressed strips is made according to the width of the profile and the joint between the window and the pre-frame.

Installing an uncompromising aluminum window requires honest and constructive collaboration between the architect, the site manager and the carpentry team.

An aluminum window made of a performance profile, installed incorrectly, will cause problems in a short time. The maximum quality of installing an aluminum window is the result of the collaboration between all the teams involved and not the team that installs the window. This collaboration does not depend on the technological equipment in the endowment, but on the willingness of each team to collaborate with the other teams.

Even if a quality installation involves several steps and a zero tolerance for compromises, the advantages obtained will be significant.

More details on how to install an aluminum window without compromise I posted on banualumin.ro